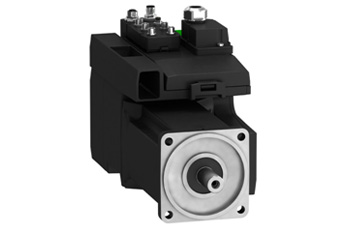

Schneider Electric, a global specialist in energy management, introduced the Lexium 32i, an integrated stand-alone servo drive for machine and plant engineering. The new drive combines the Lexium 32 servo controller and the Lexium BMH servo motor into a single unit. The servo controller is installed directly in the machine as opposed to the control cabinet, which reduces the installation effort and eliminates the need for shielded motor cables. The benefits include increased flexibility, simplified engineering, less wiring and reduced energy costs.

The compact Lexium 32i servo drive is based on a strictly modular design which allows for the configuration of numerous individual drive versions with just a few components. This allows the Lexium 32i drive to combine the advantages of an integrated servo drive – less engineering and installation effort as well as reduced space requirements in the control cabinet – with an unprecedented degree of flexibility in customizing drives to meet the needs of unique production environments.

“We are very excited about the machine design advantages introduced through the Lexium 32i servo drive,” says Greg Nelson, vice president of OEM Solutions at Schneider Electric. "The flexible, modular drive can result in savings of up to 30 percent compared to conventional servo drives. This savings stems in part from the design, which does not require cooling and works with smaller control cabinets. Additionally, reduced wiring allows for faster mounting which significantly accelerates machine commissioning."

Costs savings stem from the decreased control cabinet size, reduced wiring, and simplified installation of the Lexium 32i drive. The innovative wiring and connector concept allows the connection cables to be mounted to the top or the rear of the drive, and the drive can be adapted to the machine’s design requirements as opposed to requiring the system to adapt to the drive. The servo motor and the drive are a single unit, eliminating the need for power and encoder cables. This decreased engineering effort and the total harmonic factor during operation lead to increased machine reliability and cost savings.

Energy efficiency is integral to the design and function of the Lexium 32i. The new servo drive is installed directly in the machine, reducing the energy required to air-condition the control cabinet. The Lexium 32i features passive cooling and does not need a fan. The housing radiates the heat generated by the drive so that the outside air is sufficient for cooling at normal ambient temperatures.

The Lexium 32i is available with 70 and 100 millimeter motor flanges. The drive is supplied with either 110 to 230 V~ single-phase or 208 to 480 V ~ three-phase. Two versions are provided for fieldbus and input/output connections, industrial connectors or screw terminals. With CANopen or EtherCAT, two standard communication protocols are available for communication between the drive and the master controller and CANmotion or EtherCAT can be used as communication protocols for synchronous applications. With the available sizes, fieldbus interfaces, motor power and connection possibilities, Lexium 32i is a highly flexible, decentralized drive system in the power range of up to 2.2 kW. |